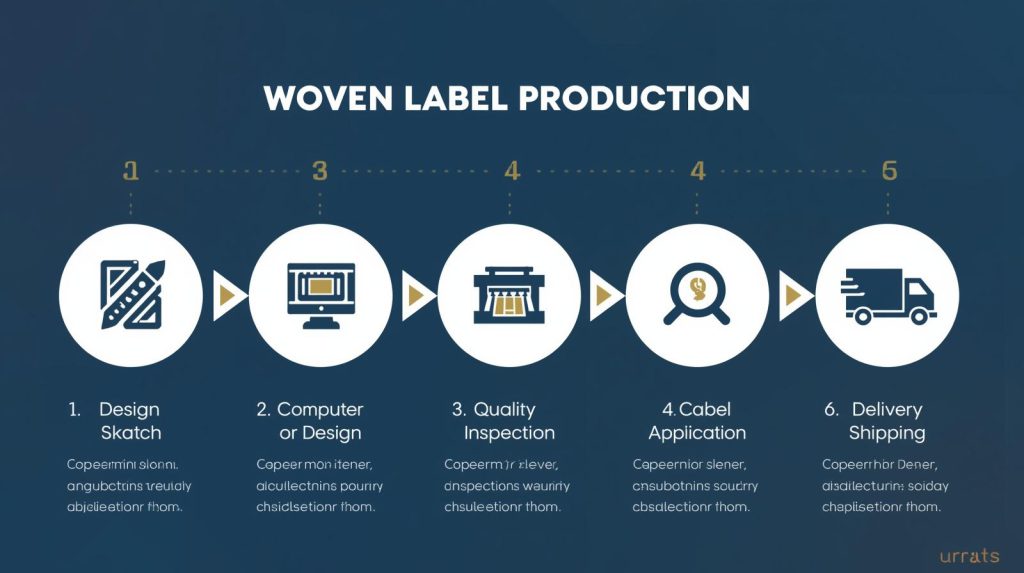

The Lifecycle of a Woven Label: From Design to Delivery

Have you ever wondered how the small but crucial labels in your clothing are made? The journey of a custom woven label from initial concept to final application on your garment involves precise craftsmanship, advanced technology, and rigorous quality control. Understanding this process helps brands appreciate the value and complexity behind these essential branding elements.

As a leading woven label manufacturer, we’re opening our doors to show you the fascinating 6-stage lifecycle of creating premium woven labels for clothing brands worldwide.

Stage 1: Design Consultation and Artwork Preparation

The journey begins with your vision. Our custom woven label process starts with a detailed design consultation where we discuss your requirements:

- Label dimensions and shape

- Color matching (using Pantone codes)

- Font selection and logo details

- Material preferences (satin, cotton, taffeta)

- Fold type (end-fold, center-fold, loop)

Pro Tip: Provide vector files (AI, EPS) for crispest results. Our design team can also help create artwork from scratch or optimize existing designs for weaving.

Start your design journey: Explore our custom label options and download our design guidelines.

Stage 2: Digital Sampling and Approval

Once we have your design specifications, we create digital mockups for your approval:

- Virtual prototypes showing exact colors and layout

- Technical specifications review

- Revisions and adjustments based on your feedback

- Final approval before production begins

This stage ensures complete alignment and prevents costly changes later in the process. Typical turnaround: 1-2 business days.

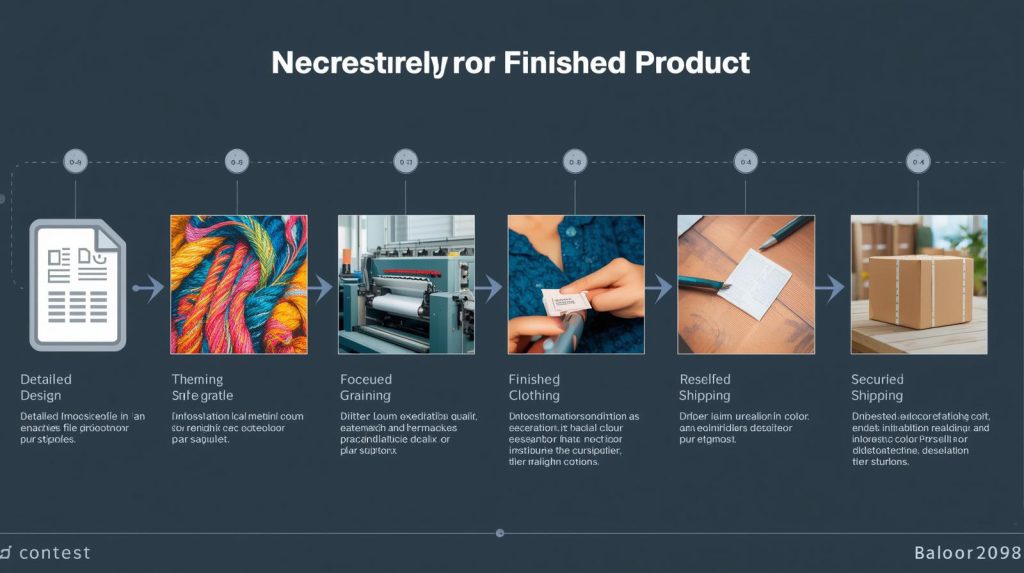

Stage 3: Loom Setup and Production Weaving

This is where the magic happens. Our advanced woven label manufacturing process involves:

A. Yarn Selection and Coloring

- High-quality polyester or cotton threads

- Precise color matching to your Pantone requirements

- Special yarns for metallic or unique effects

B. Computerized Loom Programming

- Converting your design into digital weaving instructions

- Setting up looms with exact color sequences

- Test runs to ensure quality

C. High-Speed Weaving

- Industrial looms operating at high precision

- Continuous quality monitoring during production

- Efficient production of long label rolls

See our production capabilities: Learn about our satin woven labels known for their premium quality.

Stage 4: Cutting, Folding, and Finishing

After weaving, the continuous label rolls undergo precision finishing:

A. Cutting

- Laser cutting for clean, sealed edges

- Ultrasonic cutting for precision and durability

- Size verification at every step

B. Folding

- End-folding for standard neck labels

- Center-folding for loop applications

- Mitre-cutting for premium finished corners

C. Quality Inspection

- Every label checked for defects

- Color accuracy verification

- Stitch density testing

- Size and fold precision checks

Stage 5: Quality Control and Testing

Quality is paramount in our woven label production process. Each batch undergoes rigorous testing:

- Wash resistance tests (industrial washing cycles)

- Color fastness verification

- Rub tests for durability

- Dimensional stability checks

- Visual inspection under controlled lighting

Our quality control standards ensure that every label meets international durability requirements and maintains its appearance through the garment’s lifespan.

Quality matters: Discover our premium woven labels that pass strict quality tests.

Stage 6: Packaging and Global Delivery

The final stage focuses on careful preparation for shipping:

A. Professional Packaging

- Anti-moisture packaging materials

- Organized by order and color codes

- Clear labeling for easy identification

B. Worldwide Shipping

- Reliable international shipping partners

- Tracking information provided

- Customs documentation assistance

- Flexible shipping options to meet your timeline

C. After-Sales Support

- Follow-up to ensure satisfaction

- Sample preservation for reorders

- Continuous improvement feedback

Why Choose Professional Woven Label Manufacturing?

Working with an experienced clothing label manufacturer ensures:

- Consistent Quality: Every label matches your specifications exactly

- Technical Expertise: Optimal solutions for your specific needs

- Cost Efficiency: Economies of scale and reduced waste

- Time Savings: Streamlined processes and reliable timelines

- Compliance Assurance: Meeting international standards and regulations

The Environmental Aspect: Sustainable Manufacturing

We’re committed to sustainable label production through:

- Energy-efficient manufacturing processes

- Recyclable and biodegradable materials

- Waste reduction initiatives

- Eco-friendly packaging options

Conclusion: Your Partner in Quality Branding

The journey from design to delivery involves multiple stages of precision craftsmanship and quality control. Each durable woven label represents hours of expertise, advanced technology, and commitment to excellence.

Ready to start your woven label project?

Explore our capabilities and request a quote: View Our Products